Paebbl Ramps Up CCU Production in the Netherlands, Setting the Stage for Sustainable Growth

The company is transforming carbon dioxide into innovative, green solutions for the future from Rotterdam

Nordic company Paebbl, the fastest-growing carbon dioxide (CO₂) utilization company in Europe, recently expanded to the Netherlands. The company’s strategic move to Rotterdam will allow the company to increase capacity by 100%, transitioning from lab experiments to full-scale batch production.

Paebbl’s groundbreaking carbon capture and utilization (CCU) storage technology is right at home with other stakeholders in the Dutch sustainability ecosystem. In fact, the biggest Dutch CO2 reduction program – Porthos – is also in Rotterdam. Carbon capture and storage (CCS) of CO2 will make an important contribution to national climate targets.

Just as the Netherlands supports businesses in their efforts to accelerate while benefitting people and the planet, Marta Sjögren, Co-CEO and co-founder of Paebbl, shared: “Together we aim to revolutionize the way we permanently store carbon dioxide, for the benefit of our planet”.

Transforming CO₂ for a sustainable future

Paebbl’s revolutionary technology turns captured CO₂ into a solid, eco-friendly carbonate composite—a green solution for diverse industrial needs. For every ton of CO₂ processed, Paebbl produces 2.5 tons of silica-enriched magnesium carbonate. This demonstrates a proactive approach to reducing emissions across industries. Notably, Paebbl’s silica-enriched mineral filler is making waves in eco-friendly concrete production, challenging traditional OPC cement.

The Netherlands’ sustainability initiatives propel companies like Paebbl to innovate. With goals that include embracing a circular economy by 2050, the country helps businesses drive toward more eco-friendly solutions, fostering a collaborative push for a greener future.

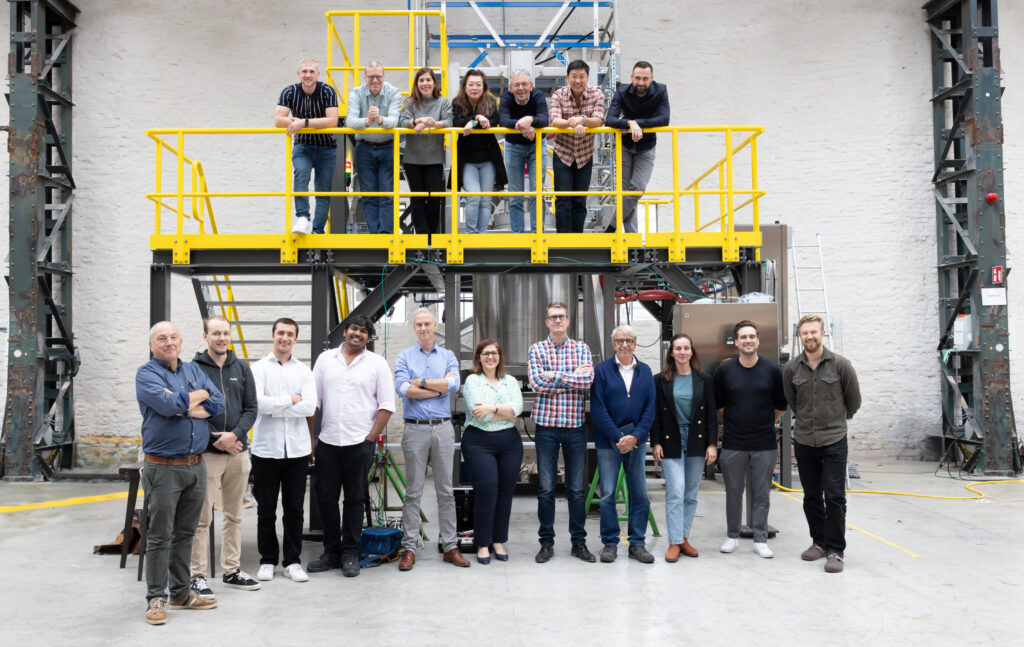

Talent that drives business success

Paebbl’s team brings a wealth of industry-specific expertise, steering the company toward success previously considered unattainable. As Paebbl accelerates into a phase of rapid expansion, the team’s experience in capital-intensive industries is pivotal in navigating the challenges associated with sustainable innovation.

“By investing in experienced and expert engineers, project managers and operators with a strong track record in the traditional industry, we can now combine this relevant experience with a startup mentality, successfully accelerating our scale-up in record time,” explained Dutch scientist Pol Knops, co-founder of Paebbl. “The plan is to rapidly develop our technology to meet the needs of both the market and the planet; there is an urgent need for alternatives to the heavy emitting raw materials of today.”

The Paebbl team includes professionals with expertise in the oil and gas, mining and chemicals sectors thanks to the robust Dutch talent pool. In fact, the Netherlands ranks among the top 5 of the Global Talent Competitiveness Index. Also recognized for its high digital literacy, proficiency in English and top-rated educational system, the country helps cultivate skilled professionals crucial to companies like Paebbl’s success. A strong workforce ensures the Netherlands maintains its business-friendly environment.

“More and more talent from traditional industries are moving into sectors focused on sustainability. The expertise emerging from these large-scale, capital-intensive, heavy industries can enable small, innovative start-ups like Paebbl to help solve many practical problems where expertise is often lacking,” explained Paebbl’s Vice President of Engineering Arnold Choi. “At Paebbl, we share a common mission and strive to accelerate innovation and make a positive impact on the world.”

An ecosystem built for Paebbl’s growth

Paebbl is turning CO₂ in products the world needs by bringing minerals and CO₂ together under high pressure and temperature. This filler is used in multiple industries such as concrete, paper, paint and polymers. Through this process, CO₂ is taken out of the lifecycle and permanently bound in different products.

The company is one of only three companies in the world that are capable of this revolutionary carbon capture and utilization (CCU) process. The plan for Paebbl’s demo plant in the Netherlands is a continuous process. Eventually, Paebbl aims to develop units that can be built in large industrial systems to capture and re-use CO2.

Source: Innovation Origins, Ondernemersbelang, Duurzaam-ondernemen

20 December 2023