Plastic Energy and SABIC to Build Advanced Chemical Recycling Plant for Plastics in the Netherlands

Pioneering facility will make significant contribution towards circular economy

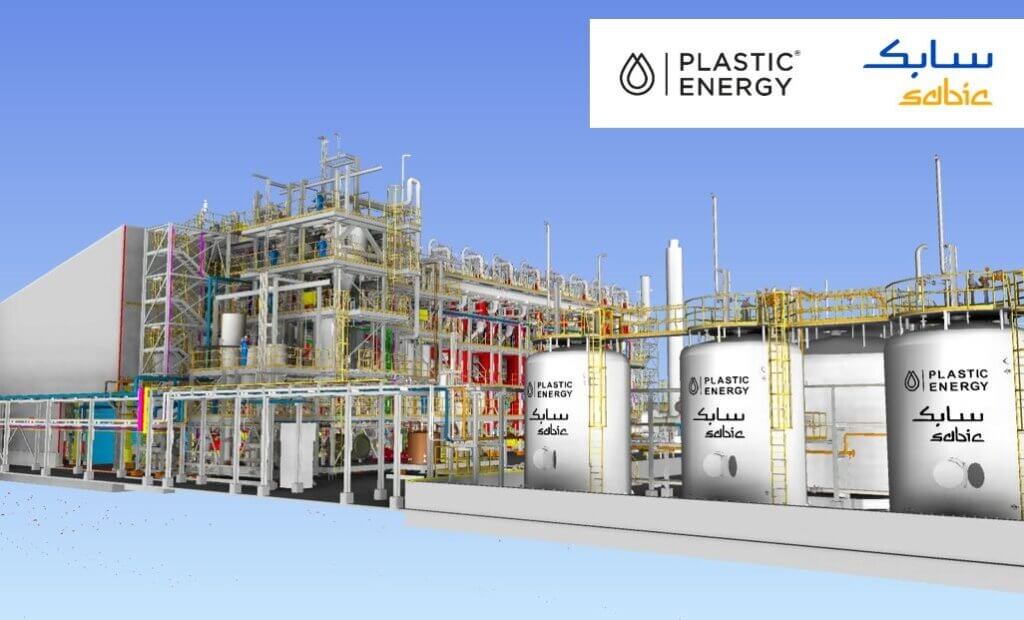

Artist’s impression. Source: Plastic Energy & SABIC

SABIC and Plastic Energy are building the world’s first commercial recycling unit to produce circular plastic polymers in the Netherlands. The plant will be a significant contribution towards the development of a circular economy for plastics.

Plastic Energy, a UK-based pioneer in chemical plastics recycling, and SABIC, a global leader in diversified chemicals, are set to start the construction of the unit. This will be based at Chemelot in Geleen, which is a key site for research & development and manufacturing in the Dutch chemicals ecosystem. The facility is expected to become operational in the second half of 2022.

The project will be realized under a 50-50 joint venture called SPEAR (SABIC Plastic Energy Advanced Recycling BV) and is being executed with a Top Sector Energy subsidy from the Ministry of Economic Affairs and Climate Policy in the Netherlands.

The Netherlands is a circular hotspot in the world

David Pappie, Director Top Sectors and Industry Policy at the Ministry of Economic Affairs and Climate Policy, said: ‘The Netherlands is a circular hotspot in the world. A great position that we want to further expand, the Netherlands must be fully circular and climate neutral by 2050.’

‘Reducing the amount of plastic plays an important role in this. For example, 1,300 kilotons of plastic waste is still incinerated annually for energy recovery. We don’t want that. We want to make high-quality products from waste plastic. We can only do this together with companies in the entire chemical recycling chain, innovative companies such as Plastic Energy and SABIC. We are working with them on circular projects that will make the Netherlands cleaner,’ Pappie explained.

Closing the loop on used plastic

Plastic Energy is in the forefront of the use and development of new technologies to transform traditionally non-recyclable plastic waste into hydrocarbon products and back into plastic. In the new plant, Plastic Energy’s recycled oils will be used by SABIC to create certified circular polymers.

‘It has been an exciting journey in making our vision of building advanced recycling plants come to life, and we are delighted to announce the construction of this new facility with SABIC,’ said Carlos Monreal, Founder and CEO of Plastic Energy. ‘We have worked jointly with SABIC towards our common goal of making plastics more sustainable and moving towards a more circular economy for plastics.”

‘Advancements in this pioneering project take us one step closer to driving the change needed to become a circular global industry,’ said Fahad Al Swailem, Vice President, PE & Sales at SABIC. ‘We have overcome significant external, global challenges to reach this important milestone and remain fully committed to closing the loop on used plastic. We are continuing to collaborate on an unprecedented level with our partners upstream and downstream to achieve this.’

SABIC, based in Saudi Arabia, has various research & development and manufacturing sites in the Netherlands. In 2019, SABIC opened its Global Technology and Innovation Center in Geleen. The company’s European headquarters and European technology center are also located in the Netherlands.

Source: SABIC and Plastic Energy press release

22 January 2021