In the Netherlands, Coolbrook Opens World’s First Electric Naphtha Cracker

The company paves way for a clean new industrial era from Brightlands Chemelot Campus

The chemical industry has taken big steps towards decarbonization of the steam-cracking process with the launch of a large-scale pilot plant in the Netherlands, by Finnish-based Coolbrook. It is the world’s first electric steam cracking for the petrochemical industry, ushering in a clean new industrial era. Coolbrook’s pilot plant is located at the Brightlands Chemelot Campus in Geleen, an innovation ecosystem for R&D, including sustainability in the chemicals industry.

The large-scale pilot plant will demonstrate the performance of the RotoDynamic Technology for steam cracking in petrochemicals, as well as high-temperature process heating across various industry sectors. Coolbrook’s investment and pilot project in the Netherlands helps to advance sustainability of the chemicals industry.

Groundbreaking event at Brightlands Chemelot Campus

At the groundbreaking of Coolbrook’s electric naphtha cracker pilot plant, politicians, industry partners, media, and other stakeholders were in attendance.

“Coolbrook’s unique technology makes a tremendous contribution to the future of electric cracking, and thus to the campus as the preferred location for sustainable innovation,” said Bert Kip, CEO of Brightlands Chemelot Campus, when the project was originally announced. The Brightlands Chemelot Campus is located at one of the largest integrated chemical sites in Europe, employing around 8000 people. It is strategically located in the center of the North-Western European chemical industry – over 40 percent of the chemical cracker capacity in the EU is located within a 200 mile radius.

The company’s RotoDynamic Technology eliminates CO2 emissions to decarbonize heavy industries. Not only can the chemical cracking process be electrified, but also across cement and steel, Coolbrook’s RotoDynamic Heaters (RDH) technology can have the potential to replace the burning of fossil fuels with high temperature electric heating to reduce carbon dioxide emissions.

“It was an honour to be able to show our technology in action after a decade of development,” said Ilpo Kuokkanen, Executive Chairman of Coolbrook. “We made history by proving that electrification can deliver the temperatures that industrial manufacturers need to achieve CO2-free production. Sharing this moment with our commercial and academic partners was a pivotal moment in our goal of full commercial production by 2024.”

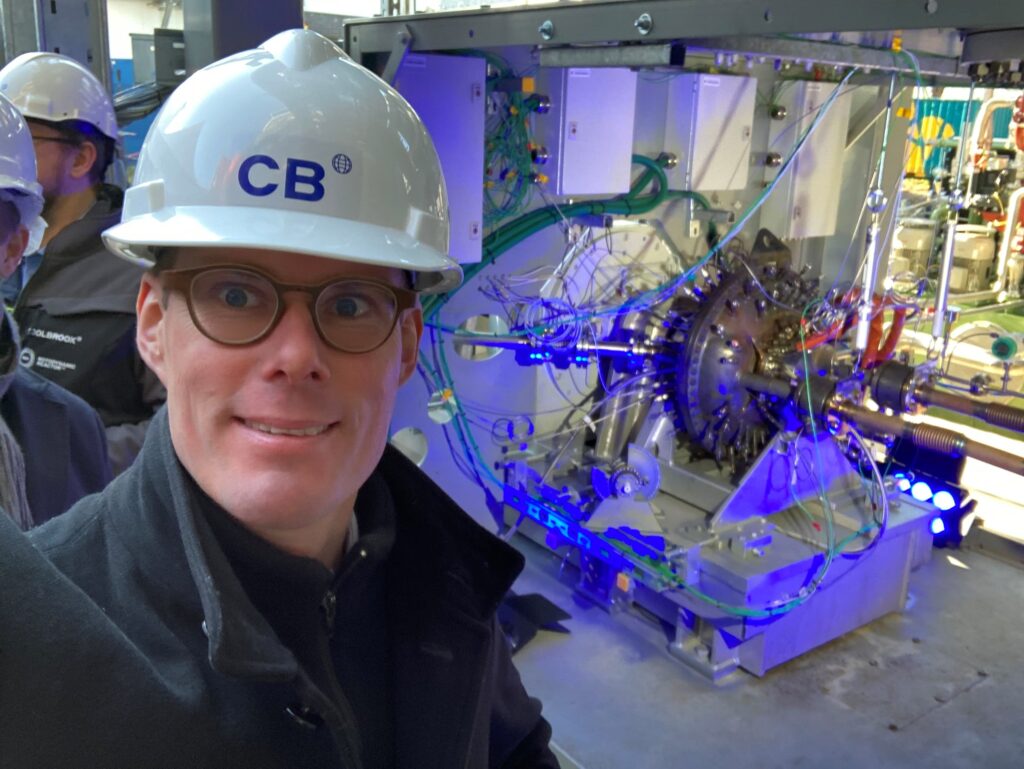

Pieter van Gent of NFIA, pictured in front of the Rotodynamic Reactor at Coolbrook’s pilot plant in the Netherlands

Global sustainability efforts and chemical advancements in the Netherlands

The growth of Coolbrook’s advancements for sustainability exemplify why the Netherlands is the place to accelerate business and benefit people and the planet. Coolbrook has already announced partnerships with ABB Energy, Braskem, CEMEX, Shell, Ultratech and ArcelorMittal to accelerate and deploy the technology in industrial facilities. Full commercial deployment of the technology is expected to start by 2025.

“We were delighted to see Coolbrook’s RotoDynamic technology, which is central to clean industrial production especially in hard-to-abate sectors, achieve this milestone,” said Colin Ward, Senior Vice President, Chemicals and Refining, ABB. “We are committed to helping reduce our customers’ annual CO2 emissions by 100 million megatons by 2030, and this partnership and successful pilot successfully showcases a future driven by electrification.”

“This pilot was a fantastic preview of what we can expect when we incorporate Coolbrook’s equipment at our plants, and watching it run in person has proved that we are on the path to decarbonising our cement production. Seeing the electrification technology we have invested in progress from theory to reality supports our Future in Action program, aimed to build a more sustainable, circular future, with the primary objective of becoming a net-zero CO2 company,” said Roberto Ponguta, VP, Operations from CEMEX.

Coolbrook’s new plant with RotoDynamic Technology is “the start of a clean new industrial era,” emphasized the company. The Dutch couldn’t agree more. The Netherlands is at the forefront of developments in sustainability and renewable industry. The Netherlands is accelerating decarbonization through hydrogen, offshore wind, Carbon Capture and Storage (CCS), energy storage, and more.

About Coolbrook

Coolbrook is an “engineering company on a mission to create a cleaner, more sustainable and profitable way to produce Olefins, the main component in the petrochemical industry and the production of plastics, chemical products, packaging and more.” In particular, the company’s technology “combines space science, turbomachinery and chemical engineering to replace the current inefficient and polluting steam cracking methods used to make Olefins with a radically cleaner and more effective alternative.” Since 2020, Coolbrook has called the Netherlands home thanks to support from the Invest in Holland Network.

Source: Coolbrook

13 December 2022